Improving insulation materials, down to wetting crossed fibres (Vol. 46 No. 5-6)

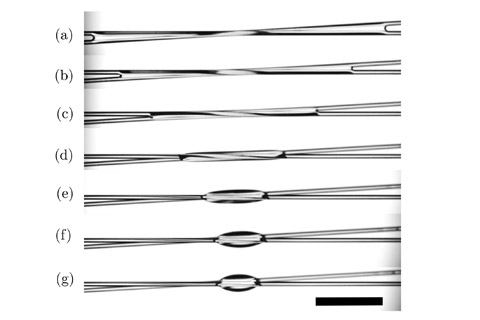

Evolution of the morphology of a drop of silicone oil on two touching crossed fibres.

Evolution of the morphology of a drop of silicone oil on two touching crossed fibres.

Scientists model the manner in which a liquid wets fibres, gaining useful insights for improving glass wool properties

Sandcastles are a prime example of how adding a small amount of liquid to a granular material changes its characteristics. But understanding the effect of a liquid wetting randomly oriented fibres in a fibrous medium remains a mystery. Relevant to the building industry, which uses glass wool, for instance, this phenomenon can be better understood by studying the behaviour of a liquid trapped between two parallel fibres. It can either remain in the shape of a drop or spread between the fibres into a long and thin column of liquid. Now, the authors have demonstrated that the spreading of the liquid is controlled by three key parameters: the amount of liquid on the fibres, the fibres’ orientation and the minimum distance between them. These findings, based on experimental and modelling work, were published recently.

A. Sauret, F. Boulogne, B. Soh, E. Dressaire and H. A. Stone, Wetting morphologies on randomly oriented fibers, Eur. Phys. J. E 38, 62 (2015)

[Abstract]